Description

What is a wet barrel fire hydrant?

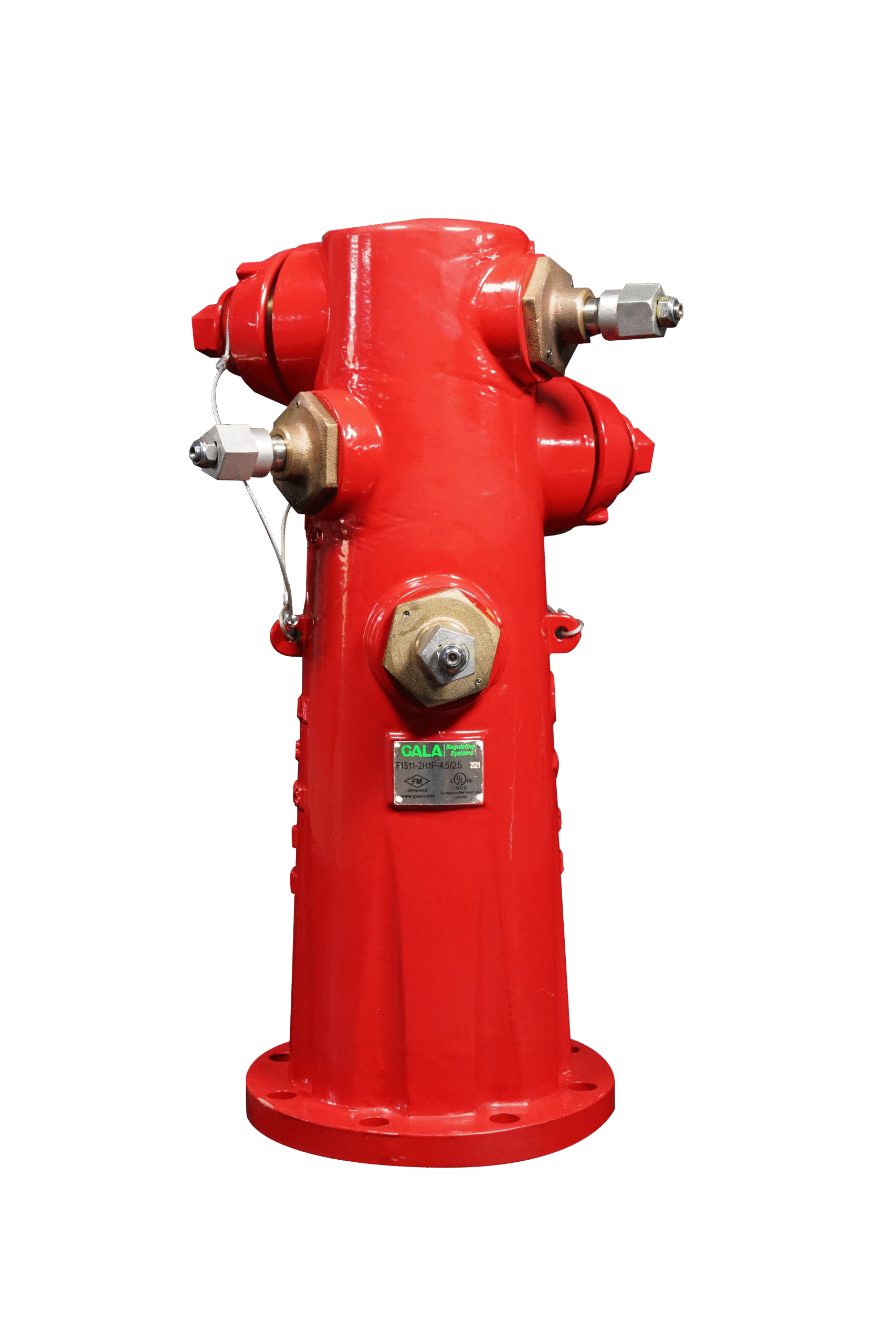

A wet barrel fire hydrant is an above-ground fire protection device that maintains pressurized water within its barrel at all times, enabling immediate water discharge during fire emergencies.

Unlike dry barrel alternatives, the wet barrel fire hydrant keeps water constantly available above the ground valve, making it ideal for climates without freezing temperatures and installations requiring rapid response capabilities.

This design features individual valves on each outlet, allowing simultaneous multi-directional water flow, a critical advantage during large-scale fire suppression operations.

Wet barrel fire hydrant sizes vary to accommodate different flow requirements, with our model engineered specifically for industrial and commercial fire protection systems. The system’s wet barrel hydrant valve configuration ensures independent outlet control, providing tactical flexibility for emergency response teams.

Product Details

Habikon Egypt’s wet barrel fire hydrant delivers exceptional performance through precision engineering and quality materials. Constructed from corrosion-resistant cast iron with a protective coating, this hydrant withstands harsh environmental conditions while maintaining structural integrity throughout its service life.

The bronze valve mechanisms ensure smooth operation and long-term reliability, even under continuous pressure.

Technical Specifications

| Specification | Value |

| Working Pressure | 250 PSI |

| Monitor Flange | 4″ (100mm) |

| Pipe Flange | 6″ (150mm) |

| Barrel Type | Wet (pressurized) |

| Material | Cast iron body, bronze internals |

| Outlet Configuration | Multiple independent valves |

| Compliance Standards | NFPA 14, NFPA 291 |

The wet barrel hydrant diagram included with installation documentation clearly illustrates connection points, valve locations, and proper operational procedures. Each outlet features standardized threading compatible with fire department equipment, ensuring seamless emergency response coordination.

Ready to enhance your fire protection system?

Contact Habikon Egypt today for technical specifications and project consultation.

Benefits & Use Cases

The wet barrel fire hydrant represents a critical component in comprehensive fire safety infrastructure, providing immediate water access that can mean the difference between containment and catastrophe.

Its pressurized design eliminates priming time, delivering instant flow rates that meet NFPA requirements for various occupancy classifications.

Key Advantages

- Instant Water Access: Pressurized barrel eliminates delay, providing immediate flow upon valve operation—critical during the first minutes of fire response

- Multi-Point Discharge: Independent outlet valves enable simultaneous hose connections from multiple directions, supporting coordinated firefighting efforts

- Reduced Maintenance: Simpler mechanism than dry barrel systems means fewer moving parts and lower long-term maintenance requirements

- Visual Inspection: Above-ground valves allow quick operational checks without excavation or specialized tools

- Freeze-Proof Installation: Perfect for Egypt’s climate, where sub-zero temperatures aren’t a concern

Practical Applications Across Industries:

- Healthcare Facilities: Hospitals and medical centers require uninterrupted fire protection that doesn’t compromise patient safety.

Wet barrel hydrants provide reliable coverage for multi-story buildings and high-occupancy areas where evacuation challenges demand superior fire suppression capabilities.

- Manufacturing & Industrial Plants: Chemical processing facilities, textile factories, and production warehouses face elevated fire risks from machinery, materials, and processes.

These hydrants offer the high flow rates necessary for industrial fire protection while withstanding exposure to chemicals and outdoor elements.

- Commercial Complexes: Shopping malls, office towers, and mixed-use developments benefit from strategically positioned wet barrel hydrants that provide comprehensive coverage across extensive properties.

The system’s instant readiness supports both fire department operations and on-site emergency response protocols.

- Logistics & Storage: Warehouses storing combustible materials require robust fire protection infrastructure.

The 250 PSI working pressure delivers the flow capacity needed for large-area suppression, while multiple outlets enable tactical positioning during warehouse fires where access may be limited.

- Educational Institutions: Schools, universities, and training centers protect students and staff with reliable fire hydrant systems positioned throughout campus grounds, ensuring rapid response capability in high-occupancy educational environments.

Why Choose Wet Barrel Fire Hydrants from Habikon Egypt?

Habikon Egypt stands as Egypt’s trusted partner for comprehensive fire protection solutions, combining international product quality with local expertise and support.

Our wet barrel fire hydrant systems come from manufacturers certified to international safety standards, ensuring your investment delivers performance that meets both NFPA guidelines and Egyptian Civil Defense requirements.

What Sets Habikon Apart:

- Internationally Certified Products: We source fire hydrants from manufacturers holding ISO 9001 certification and products tested to NFPA 14 and NFPA 291 standards, guaranteeing equipment reliability when seconds matter most.

- Complete Compliance Assurance: Our technical team ensures every installation meets Egyptian fire code requirements, NFPA standards, and insurance specifications. We handle documentation, testing, and certification coordination throughout your project lifecycle.

- End-to-End Project Capabilities: From hydraulic calculations and system design through procurement, installation, testing, and commissioning, Habikon manages every phase. Our integrated approach eliminates coordination gaps that compromise project timelines and system performance.

- Proven Industrial Track Record: With successful projects across manufacturing facilities, commercial developments, healthcare institutions, and logistics centers, Habikon brings real-world experience to your fire protection challenges.

We understand the unique requirements of Egyptian projects and regulatory environments.

- Technical Support & Training: Our commitment extends beyond installation. Habikon provides operational training for facility teams, maintenance guidance, and ongoing technical support, ensuring your fire protection system maintains peak readiness throughout its service life.

To discuss your project requirements and discover how our wet barrel fire hydrant systems integrate into comprehensive safety solutions.

Request a consultation with Habikon’s fire protection specialists

FAQs

What is the difference between wet and dry barrel fire hydrants?

Wet barrel hydrants maintain pressurized water above ground with individual outlet valves, providing instant water access. They’re ideal for warm climates like Egypt, where freezing isn’t a concern, offering simpler operation than dry barrel alternatives.

Are Habikon’s wet barrel fire hydrants NFPA compliant?

Yes, our fire hydrants meet NFPA 14 and NFPA 291 standards for installation, performance, and flow testing. We provide complete certification documentation required for civil defense approval and insurance compliance in Egyptian projects.

What maintenance does a wet barrel fire hydrant require?

Quarterly visual inspections, annual flow testing, and valve lubrication constitute typical maintenance.

Habikon provides detailed maintenance protocols and can offer ongoing service agreements to ensure continuous compliance and operational readiness throughout the hydrant’s lifespan.

Can this fire hydrant integrate with existing fire protection systems?

Absolutely. The 6″ pipe flange connects to standard fire protection piping, while standardized outlet threading ensures compatibility with fire department equipment.

Habikon’s engineering team performs hydraulic analysis to verify proper integration with your existing infrastructure.

What’s included with fire hydrant installation from Habikon?

Our comprehensive installation includes site preparation, underground piping connections, hydrant mounting, pressure testing, flow testing, documentation, and coordination with authorities.

We handle permitting, provide as-built drawings, and ensure full system commissioning before project handover.

Reviews

There are no reviews yet.