Description

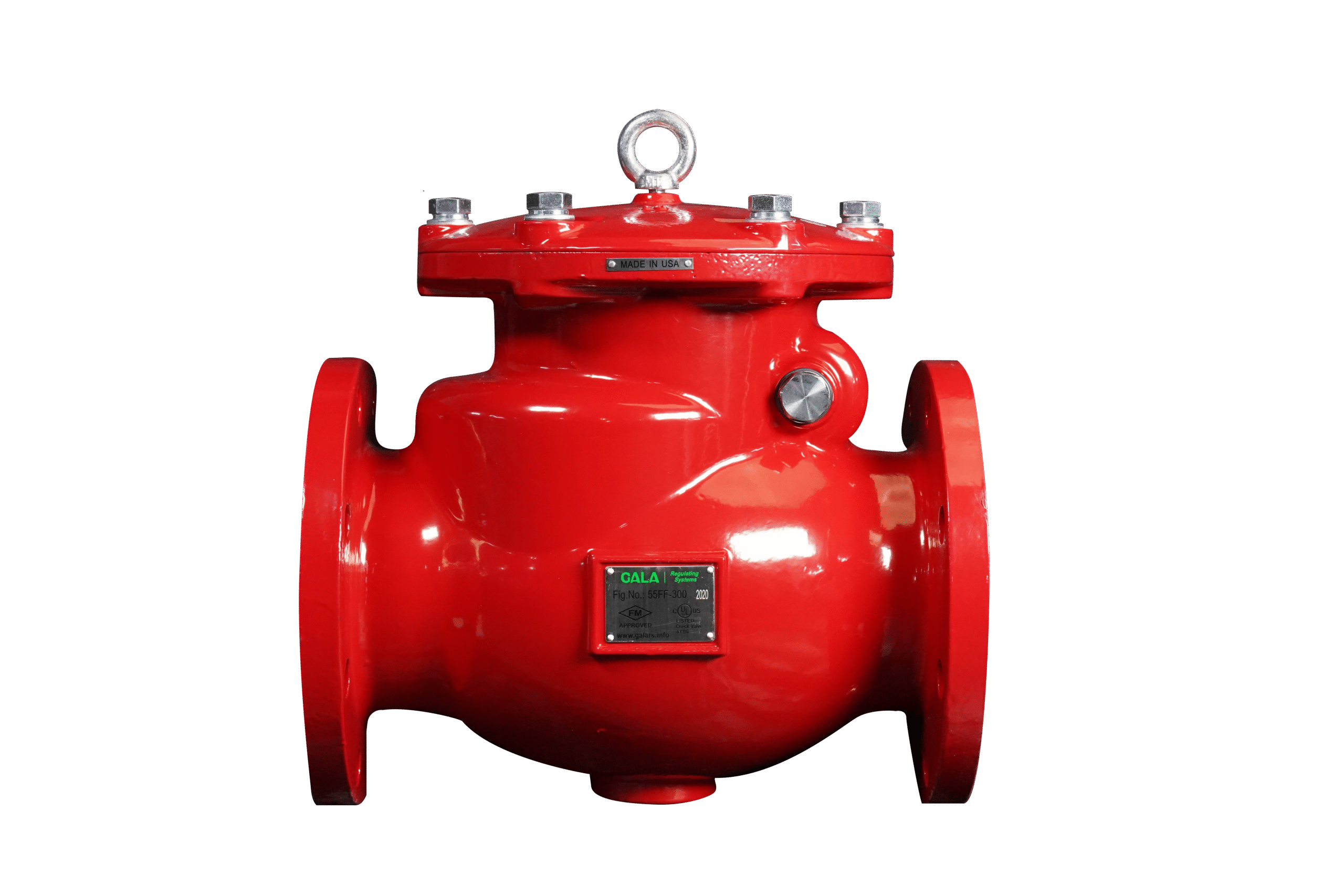

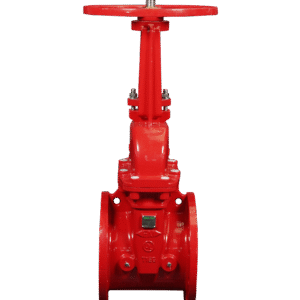

What is a Swing Check Valve?

A swing check valve (In piping schematics, the swing check valve is typically shown using the non-return valve symbol, representing one-way flow) is a mechanical device that allows fluid to pass in one direction while automatically preventing reverse flow.

It operates through a hinged disc mechanism that swings open with forward flow and closes when flow reverses, ensuring reliable protection against back pressure.

This design is particularly useful in fire protection networks, HVAC systems, and water distribution lines, where the check valve cracking pressure and reliability are crucial for system safety.

Product Details

The GALA Swing Check Valve Fig. 58FF-365, available at Habikon Egypt, combines durability and precision engineering for dependable performance in demanding environments.

Technical Overview

| Specification | Details |

| Standard | AWWA C508 / C550 |

| Working Pressure | 365 PSI |

| Temperature Range | -10°C to 120°C |

| Connection Ends | FF–GG (Flanged Ends) – Compliant with EN1092-2 PN10/PN16 standards |

| Body Material | Ductile Iron (ASTM A536 65-45-12) |

| Disc | Ductile Iron (ASTM A536 65-45-12) |

| Seat | Brass B271 C83600 |

| Shaft & Fittings | Stainless Steel SS304 |

| Sealing Ring | EPDM |

| Available Sizes | 2” to 24” (DN50–DN300) |

The valve’s FF-GG flanged ends ensure a tight seal and easy installation, while the EPDM sealing ring provides leak-proof operation under fluctuating pressures. Designed for long-lasting reliability, this model performs flawlessly across both commercial and industrial settings.

Benefits & Use Cases

Key Benefits

- Prevents backflow automatically without external control.

- Handles high-pressure systems up to 365 PSI.

- Resistant to corrosion and wear due to SS304 components.

- Simple design ensures easy inspection and maintenance.

- Compatible with international standards and multiple system types.

Applications

The swing check valve is ideal for:

- Firefighting systems: ensure an uninterrupted water supply to sprinklers and hydrants.

- Hospitals & Banks: maintain reliable system performance and hygiene.

- Factories & Warehouses: protects mechanical systems from reverse flow damage.

- Commercial buildings & Security facilities: ensures compliance with fire codes and NFPA standards.

By preventing water hammer and maintaining one-way flow, this valve enhances system safety, extends equipment lifespan, and ensures compliance in critical installations.

Why Choose Swing Check Valve from Habikon Egypt?

Habikon Egypt is a trusted distributor and MEP contractor specializing in fire protection and mechanical systems. Our swing check valve range stands out for:

- Internationally certified quality – compliant with AWWA, EN, and BS standards.

- NFPA and local fire code compliance for safety-critical projects.

- Expert design, supply, and installation by experienced engineers.

- Proven success across hospitals, factories, and commercial complexes.

- Comprehensive after-sales support and project management expertise.

When you choose Habikon Egypt, you choose performance, safety, and long-term reliability for your fire protection systems.

Contact Habikon Egypt today for technical consultation or a custom quote

FAQs

1. How to install a swing check valve?

Install the valve in the horizontal or vertical position (flow upwards) with the arrow on the body indicating the direction of flow. Ensure proper alignment of the flanged ends and avoid stress on the pipeline during tightening for best sealing performance.

2. Is a swing check valve a backflow preventer?

Yes. A swing check valve automatically closes when reverse flow occurs, effectively acting as a backflow preventer in piping and fire protection systems.

3. What are the three main types of check valves?

The main types include swing check valves, lift check valves, and spring (or silent) check valves, each designed for specific flow and pressure conditions.

4. What is the difference between swing and non-slam check valves?

A swing check valve uses a hinged disc that swings freely, while a non-slam check valve closes faster using a spring mechanism to minimize water hammer in high-velocity systems.

5. What’s the difference between a swing check valve and a spring check valve?

The swing type relies on gravity or reverse flow to close, suitable for large flow rates, while the spring type uses internal tension for faster closure in high-pressure or vertical systems.

6. What operation condition is suitable for a swing check valve?

It is ideal for low to medium flow velocities in horizontal or upward vertical pipelines, handling clean water or fire suppression fluids under pressure up to 365 PSI.

Reviews

There are no reviews yet.