Description

What is an End Suction Fire Pump BS EN 733?

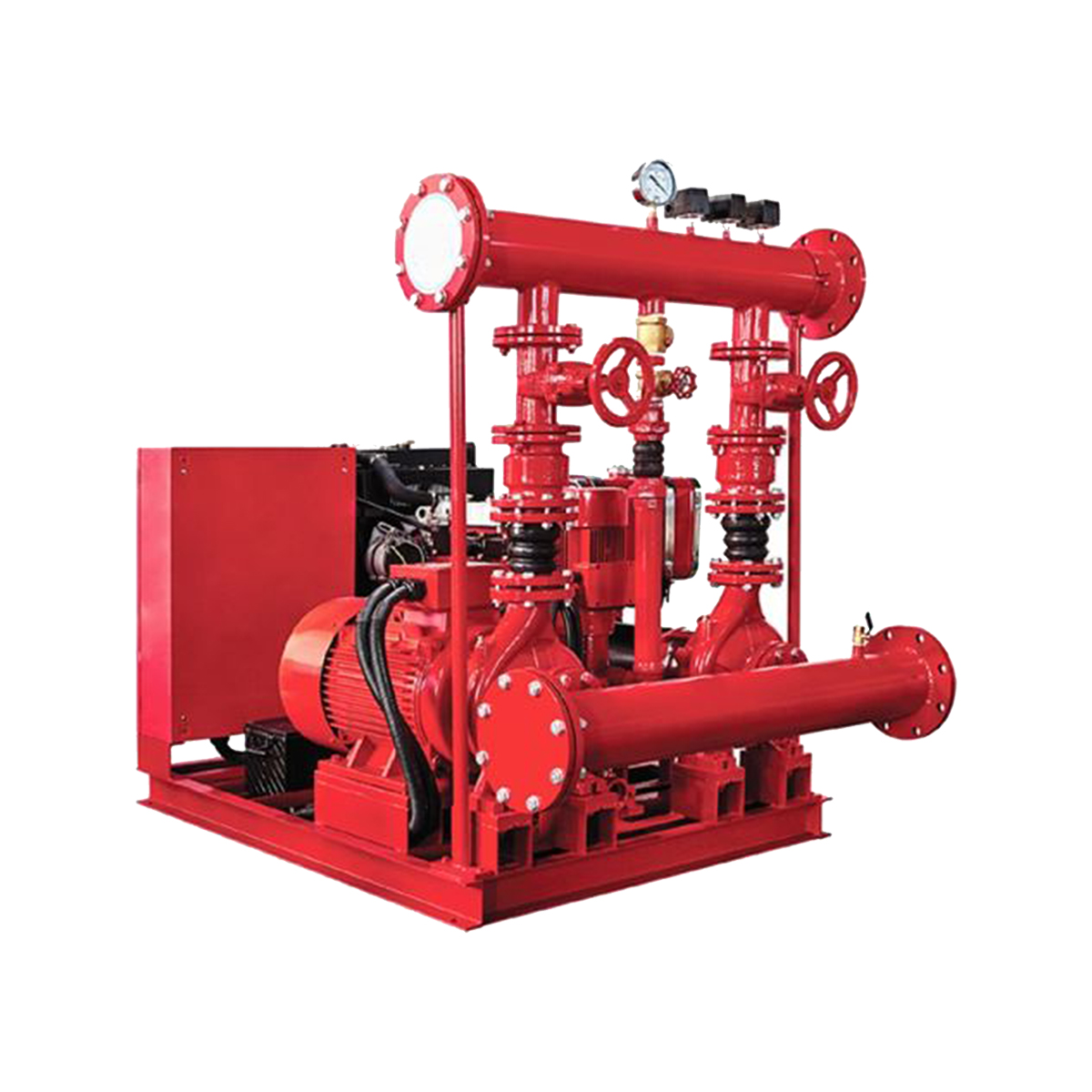

Reliable water supply during fire emergencies can mean the difference between minor damage and catastrophic loss. An End-Suction Fire Pump, as specified in BS EN 733, is a centrifugal pump designed specifically for fire protection applications, manufactured according to the British Standard EN 733 specifications.

This standard defines dimensional interchangeability, performance requirements, and construction criteria, ensuring consistent quality across manufacturers.

The end-suction fire pump BS EN 733 features a horizontal, single-stage design, where water enters axially through the suction flange and discharges radially at 90 degrees, providing efficient hydraulic performance for fire suppression demands.

These pumps serve as the primary water supply source for buildings where municipal pressure is insufficient or where code requires dedicated fire protection pumping.

Understanding the end suction fire pump BS EN 733 manual specifications ensures proper selection based on flow rate, discharge pressure, and system hydraulic calculations per NFPA requirements.

Product Details

Habikon Egypt supplies comprehensive fire pump packages engineered for maximum reliability throughout their operational lifespan. Each system integrates electric motor-driven pumps, diesel backup pumps, jockey pumps, and complete control assemblies mounted on robust steel frameworks.

System Configuration & Technical Specifications

| Component | Specification | Standards Compliance |

| Primary Pump Type | End Suction Centrifugal | BS EN 733, NFPA 20 |

| Drive Options | Electric Motor / Diesel Engine | UL/FM Listed |

| Capacity Range | 250 GPM: 2500 GPM (customizable) | Per hydraulic calculations |

| Discharge Pressure | Up to 175 PSI (variable) | System-specific |

| Jockey Pump | Vertical Multistage | Pressure maintenance |

| Construction Material | Cast Iron / Ductile Iron / Bronze fitted | Corrosion-resistant |

| Control System | Individual pressure sensing per pump | NFPA 20 compliant |

| Mounting | Structural steel base frame | Seismic rated available |

Included System Accessories

- Suction Piping: Properly sized inlet with eccentric reducer (no strainers per NFPA 20)

- Discharge Assembly: Flanged connections, butterfly valve, check valve, OS&Y gate valve

- Instrumentation: Pressure gauges (suction/discharge), pressure switches, flow meters

- Flexible Connections: Expansion joints for vibration isolation and thermal expansion

- Control Panels: Electric motor starters, diesel engine controllers, automatic transfer capability

- Test Headers: Circulation relief valve and flow testing provisions

The system operates automatically through pressure-sensing controls that activate pumps when system pressure drops below setpoints, ensuring immediate response to sprinkler activations or hydrant usage without manual intervention.

Get a technical hydraulic analysis and pump sizing calculation for your facility.

Benefits & Applications of End Suction Fire Pump BS EN 733

Fire pumps represent the heart of active fire protection systems, converting stored or municipal water into the pressurized flow necessary for effective suppression. Their reliability directly impacts life safety and property preservation during critical fire events.

- Maximum Operational Reliability: Engineered specifically for fire service with robust construction, these pumps deliver consistent performance throughout their expected 25+ year lifespan with minimal maintenance when properly specified and installed.

- Code-Compliant Design: BS EN 733 and NFPA 20 compliance ensures hydraulic performance, material selection, and installation practices meet international fire protection standards, satisfying insurance requirements and regulatory inspections.

- Redundant Protection: Complete packages include electric primary pumps with diesel backup and pressure-maintenance jockey pumps, guaranteeing water supply even during power outages or equipment failures when reliability matters most.

- Individual Pressure Sensing: Each pump controller monitors system pressure independently through dedicated sensing lines, providing accurate activation control and preventing interference between multiple pump controllers.

- Rapid Response Activation: Automatic pressure-based starting delivers water within seconds of sprinkler activation, maintaining adequate pressure and flow for effective fire suppression without waiting for manual intervention.

- Versatile Application Range: Capacity options from 250 to 2500+ GPM accommodate diverse building types from small commercial structures to large industrial complexes, with custom configurations available for unique hydraulic requirements.

Real-World Applications with Proven Results

- Healthcare Facilities (750-1,500 GPM typical): Hospitals and medical centers across Egypt rely on UL/FM-listed End Suction Fire Pump BS EN 733 systems, providing a reliable water supply to extensive sprinkler networks. During a recent Cairo hospital incident, the fire pump activated automatically, supplying 950 GPM at 110 PSI to control a medical equipment fire before significant damage occurred.

- Manufacturing Plants: Industrial facilities with high-challenge fire hazards install high-capacity fire pumps (1000-2500 GPM) supplying deluge systems, foam proportioning equipment, and large-orifice sprinklers protecting machinery and flammable material storage.

- Commercial High-Rises: Office towers and residential buildings exceeding municipal water pressure capabilities depend on fire pumps delivering adequate pressure to upper-floor sprinkler systems and standpipe connections for firefighter hose streams.

- Warehouse Distribution Centers: Logistics facilities protecting high-rack storage with ESFR sprinklers require substantial fire pump capacity (1500+ GPM) to maintain the high pressures necessary for effective fire control in challenging storage configurations.

- Shopping Centers: Retail complexes install fire pump systems supplying water to sprinkler networks protecting multiple tenant spaces, common areas, and parking structures where municipal pressure proves insufficient.

- Hotels & Hospitality (600-1,400 GPM typical): Guest accommodation facilities utilize BS EN 733 compliant pump packages meeting life safety codes for multi-story buildings, ensuring adequate sprinkler protection and standpipe supply for emergency responder access during evacuation scenarios.

Why Choose End Suction Fire Pump BS EN 733 from Habikon Egypt?

Habikon Egypt stands as Egypt’s premier fire protection systems contractor with over 150 successful fire pump installations across healthcare, industrial, and commercial facilities.

Our ISO 9001-certified engineering team and Egyptian Civil Defense-approved contractor status ensure your project receives the technical expertise and regulatory knowledge critical for code-compliant, reliable fire protection infrastructure.

What we offer:

- Certified Products & Compliance: We supply UL/FM-listed End Suction Fire Pump BS EN 733 systems meeting NFPA 20 and BS EN 733 standards. All equipment includes factory certifications, performance curves, and traceability documentation required for authority approval.

- Engineering & Design: Our certified engineers provide hydraulic calculations, pump selection, NPSH analysis, and stamped drawings per the end suction fire pump BS EN 733 manual specifications. We handle all authority submissions and approvals.

- Complete Project Execution: From equipment procurement and installation supervision through performance testing and commissioning, we deliver turnkey solutions. Our portfolio includes major hospitals, manufacturing plants, and government facilities with documented successful commissioning.

- Competitive Pricing: Direct manufacturer relationships enable cost-effective end suction fire pump BS EN 733 price points while maintaining quality and compliance standards.

- Maintenance & Support: We offer NFPA 25-compliant maintenance contracts, including weekly inspections, annual flow testing, and emergency repair services with full documentation for compliance records.

Schedule a technical consultation and receive detailed specifications.

Contact Habikon Egypt now for project quotations

FAQs

What is the NFPA standard for fire pumps?

NFPA 20 governs fire pump installation, specifying pump selection, driver requirements, controller features, piping arrangements, and acceptance testing procedures. NFPA 25 covers ongoing inspection, testing, and maintenance requirements, ensuring continued reliability throughout the system’s operational life.

What is a normal suction pressure for fire pumps?

Typical suction pressure ranges from 0 to 50 PSI positive for pumps fed from elevated tanks or pressurized sources. Municipal supply connections often provide 40-80 PSI. Suction lift (negative pressure) up to 10 feet is permissible but requires careful NPSH analysis.

How to calculate the maximum suction pressure of a pump?

Maximum suction pressure equals pump casing pressure rating minus rated discharge pressure minus safety margin. For example, a 175 PSI-rated pump at 100 PSI discharge allows approximately 50-60 PSI maximum suction pressure, preventing casing over-pressure conditions.

How long does a fire pump installation take?

Standard installation requires 2-4 weeks, depending on pump room preparation, electrical service availability, and piping complexity. Habikon Egypt provides detailed project schedules during the proposal phase and coordinates all trades for seamless execution with minimal disruption.

What is the 10X rule for fire pumps?

The 10X rule states suction piping diameter should be sized so velocity never exceeds 10 feet per second, preventing excessive friction loss and ensuring adequate NPSH (Net Positive Suction Head) for reliable pump operation without cavitation damage.

What maintenance do BS EN 733 fire pumps require?

NFPA 25 requires weekly visual inspections, monthly controller tests, quarterly diesel engine runs, annual flow testing, and periodic overhauls based on service hours. Habikon Egypt offers comprehensive maintenance contracts ensuring compliance and system readiness.

Reviews

There are no reviews yet.