Check valves are critical components in any piping system where backflow prevention is necessary. Whether you’re designing a fire protection system for a hospital in Cairo, managing an industrial facility, or overseeing an HVAC installation, understanding check valve types and applications ensures system reliability and safety.

This complete guide covers all major types of check valves in piping systems, from swing check valves to specialized foot valves. You’ll learn how to select the right valve type based on pressure, flow, and installation requirements with specific guidance for fire protection applications common in Egyptian projects.

What Is a Check Valve?

A check valve is a one-way valve that allows fluid to flow in only one direction while automatically preventing backflow. Unlike other valve types that require manual operation, these valves work automatically based on pressure differential.

The valve opens when forward pressure from the fluid exceeds the valve’s cracking pressure. When the flow stops or reverses direction, it closes to prevent backflow.

These devices protect pumps, prevent contamination, maintain system pressure, and ensure the proper operation of fire protection and water supply systems.

Why Check Valves Are Essential in Piping Systems

- Pump Protection

Check valves prevent reverse flow that could damage pumps or cause motor burnout when pumps stop operating.

- System Pressure Maintenance

In multi-story buildings and pressurized systems, these valves maintain pressure zones and prevent gravity-fed backflow.

- Contamination Prevention

They prevent contaminated water from flowing back into clean water supplies, which is critical in hospitals and pharmaceutical facilities.

- Fire Protection System Integrity

In firefighting systems, check valves ensure water flows only toward sprinklers and standpipes, maintaining system readiness and compliance with fire protection standards.

- Energy Efficiency

By preventing backflow, these valves reduce unnecessary pump cycling and energy consumption in HVAC and industrial systems.

Types of Check Valves

Understanding the different types of check valves in piping helps engineers specify the right solution for each project requirement. Each valve type offers distinct performance characteristics suited to specific applications.

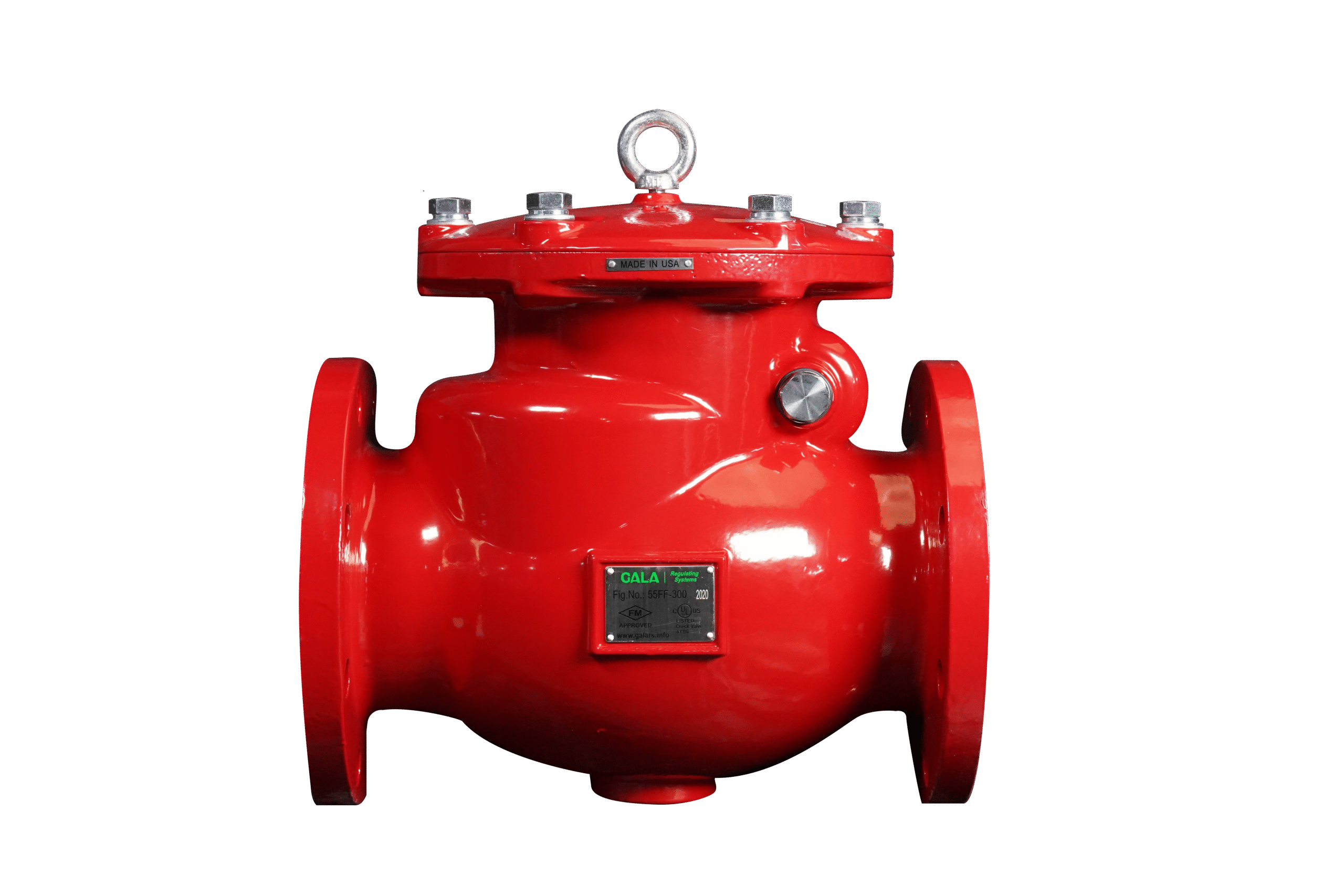

Swing Check Valve

The swing check valve is one of the most common hydraulic check valve types used in large piping systems. It uses a hinged disc that swings open with forward flow and closes when flow stops or reverses.

How it works:

The disc pivots on a hinge pin mounted above the flow path. Forward pressure swings the disc open, allowing full flow. When flow stops, gravity and reverse pressure swing the disc back to the closed position against the valve seat.

| Feature | Specification |

| Best Pipe Sizes | 100 mm and above |

| Pressure Drop | Low (minimal flow resistance) |

| Installation | Horizontal preferred |

| Pressure Rating | PN10 to PN40 |

| Maintenance | Low frequency |

| Typical Applications | Large fire systems, water treatment, industrial process lines |

Advantages:

- Low pressure drop during operation

- Suitable for large pipe sizes

- Simple valve body design with fewer parts

- Long service life in proper applications

Limitations:

- Potential for water hammer in high-velocity systems

- Requires horizontal installation for gravity-assisted closing

- Larger face-to-face dimension than other types

Lift Check Valve

Lift check valves use a disc or piston that lifts vertically from the valve seat when forward pressure exceeds the spring or gravity force holding it closed.

How it works:

Flow enters from below, lifting the disc against gravity or spring force. When flow stops, the disc drops back onto the seat, sealing the valve. The guided disc movement ensures consistent check valve performance.

| Feature | Specification |

| Best Pipe Sizes | 25 mm to 150 mm |

| Pressure Drop | High |

| Installation | Vertical preferred |

| Pressure Rating | PN16 to PN100+ |

| Maintenance | Medium frequency |

| Typical Applications | High-pressure systems, steam lines, vertical piping |

Advantages:

- Excellent sealing performance

- Works well in high-pressure applications

- Suitable for vertical installations

- Available with spring assistance for faster closing

Limitations:

- Higher pressure drop than swing check valves

- Limited to smaller pipe sizes

- More sensitive to debris and fouling

Wafer Check Valve

Wafer check valves are compact, lightweight valves installed between pipe flanges without requiring separate bolting for the valve itself.

How it works:

A spring-loaded disc opens with forward flow and closes quickly when flow stops, held by spring tension between the flanges. This design minimizes flow resistance while maintaining positive sealing.

| Feature | Specification |

| Best Pipe Sizes | 25 mm to 300 mm |

| Pressure Drop | Medium |

| Installation | Any orientation |

| Pressure Rating | PN10 to PN25 |

| Maintenance | High (requires system disassembly) |

| Typical Applications | HVAC systems, building services, fire risers |

Advantages:

- Compact design saves space

- Lower installation cost

- Lighter weight than flanged valves

- Fast closing reduces water hammer risk

Limitations:

- Not suitable for high-pressure applications

- Difficult to service without system shutdown

- Spring can fatigue over time

Dual Plate Check Valve

Also called butterfly or double-door check valves, these use two spring-loaded semicircular discs that swing open from a central hinge.

How it works:

Forward flow pushes both plates open against spring tension. When flow decreases, springs assist closure before backflow occurs, preventing water hammer and pressure surges.

| Feature | Specification |

| Best Pipe Sizes | 50 mm to 600 mm |

| Pressure Drop | Medium |

| Installation | Any orientation |

| Pressure Rating | PN10 to PN40 |

| Maintenance | Medium frequency |

| Typical Applications | Fire protection, pump discharge, industrial water |

Advantages:

- Excellent for preventing water hammer

- Compact face-to-face dimension

- Lower weight than swing check valve types

- Suitable for horizontal and vertical installation

Limitations:

- More complex valve body design with more parts

- Higher initial cost

- Requires periodic spring maintenance

Ball Check Valve

Ball check valves use a spherical ball that moves freely within the valve body to allow or block flow based on flow direction.

How it works:

Forward flow pushes the ball away from the inlet seat. Reverse flow or gravity forces the ball back against the seat to seal. The simple mechanism handles solids effectively.

| Feature | Specification |

| Best Pipe Sizes | 15 mm to 100 mm |

| Pressure Drop | Medium-high |

| Installation | Any orientation |

| Pressure Rating | PN10 to PN25 |

| Maintenance | Low frequency |

| Typical Applications | Pump discharge, sump pumps, drainage systems |

Advantages:

- Simple, rugged design

- Handles fluids with solids

- Works in any orientation

- Low maintenance

Limitations:

- Noisy operation

- Less precise sealing than disc types

- Not suitable for high-pressure systems

Foot Valve

A foot valve is a specialized check valve installed at the suction end of a pump intake line, typically submerged in a tank or sump.

How it works:

The valve opens during pump operation and closes when the pump stops, maintaining prime in the suction line and preventing pump cavitation.

| Feature | Specification |

| Best Pipe Sizes | 25 mm to 200 mm |

| Pressure Drop | High |

| Installation | Submerged only |

| Pressure Rating | PN6 to PN16 |

| Maintenance | High (strainer cleaning) |

| Typical Applications | Above-ground pumps, water wells, tank suction |

Advantages:

- Maintains pump prime

- Includes a strainer for debris protection

- Prevents pump cavitation

Limitations:

- Higher pressure drop than other types

- Requires submersion

- The strainer requires periodic cleaning

Need help selecting the right check valve for your project? Our engineering team provides technical consultation for valve selection, system design, and Egyptian Code compliance.

Contact Habikon to discuss your fire protection or MEP system requirements.

Check Valve Materials and Construction

Selecting appropriate check valve materials ensures long-term performance and compliance with system requirements. Material choice affects durability, cost, and suitability for specific fluids and temperatures.

| Material | Temperature Range | Pressure Rating | Best Applications | Corrosion Resistance | Relative Cost |

| Brass | Up to 120°C | PN10 to PN25 | Potable water, HVAC, light commercial | Good for water | Low-Medium |

| Stainless Steel | Up to 250°C | PN16 to PN100 | Chemical processing, food/beverage, marine | Excellent | High |

| Cast Iron | Up to 200°C | PN10 to PN40 | Water distribution, sewage, and industrial cooling | Fair (non-corrosive fluids) | Low |

| Bronze | Up to 150°C | PN10 to PN40 | Marine, seawater, dezincification concerns | Excellent for seawater | Medium |

| PVC/Plastic | Up to 60°C | PN6 to PN16 | Corrosive chemicals, industrial processes | Excellent for chemicals | Low |

Material Selection Criteria:

Consider fluid type, temperature range, pressure rating, corrosion potential, and budget when selecting check valve materials. For fire protection systems in Egypt, ductile iron or stainless steel typically meets code requirements and ensures reliability.

Read More: OS&Y Valves

Check Valve Symbols and Technical Drawings

Engineers use standardized check valve symbols on piping and instrumentation diagrams (P&IDs) to communicate system design clearly.

| Valve Type | Symbol Description | Key Features | Standard Reference |

| Standard Check Valve Types | Circle/diamond with arrow and barrier line | The arrow shows permitted flow direction | ISO 1219, ISO 4126 |

| Swing Check Valve Types | Circle with hinged disc indicator | Shows the swing mechanism | ISO 1219 |

| Lift Check Valve Types | Vertical disc movement indicator | Notes vertical installation | ISO 1219 |

| Dual Plate Check Valve Types | Two plates opening from the center | Spring indicators included | ISO 4126 |

Symbol Standards:

ISO 1219 and ISO 4126 provide international standards for valve symbols. Egyptian engineering drawings typically follow ISO standards or British Standards (BS) for consistency across trades. Understanding these symbols ensures proper valve selection and installation during project execution.

When reviewing fire protection system drawings, verify that check valve symbols match specifications. Incorrect symbol interpretation can lead to wrong valve type selection and system performance issues.

Differences Between Check Valve Types

Choosing between check valve types depends on system requirements, installation conditions, and check valve performance priorities.

- Pressure Drop Considerations

Swing check valve types offer the lowest pressure drop, making them ideal for large systems where energy efficiency matters. Lift check valves and wafer types create a higher pressure drop but provide better sealing. Consider how flow resistance affects pump sizing and operating costs.

- Installation Orientation

Swing check valve types typically require horizontal installation for gravity-assisted closing. Dual plate and wafer types work in any orientation. Lift check valves are often designed for vertical installation. Verify orientation requirements before specifying.

- Closing Speed

Dual-plate check valve types close fastest, reducing water hammer risk. Swing check valves close more slowly, which can cause water hammer in high-velocity applications. Spring-assisted types offer intermediate closing speed. Match closing speed to system velocity characteristics.

- Maintenance Access

Flanged valves (swing, lift, and dual plate) can be removed for maintenance without extensive piping work. Wafer types require system disassembly. Ball and foot valves often need replacement rather than repair. Plan maintenance access during design.

- Pressure Rating

Lift check valve types handle the highest pressures, suitable for steam and high-pressure hydraulic applications. Wafer types are limited to lower-pressure applications. Swing and dual-plate types cover medium- to high-pressure ranges. Always verify that the pressure rating exceeds the system design pressure.

- Check Valve Applications by Type

Industrial applications favor swing or lift check valves for reliability. Commercial buildings often use dual-plate or wafer check valves for space efficiency. Fire protection systems typically specify dual-plate check valves for water hammer prevention and fast response.

Read more: NRS Valves

What Is the Difference Between a 2-Way and 3-Way Valve?

| Valve Type | Number of Ports | Function | Typical Use |

| 2-Way Valve | 2 (inlet + outlet) | Opens/closes single flow path | Check valves, isolation valves |

| 3-Way Valve | 3 (1 inlet + 2 outlets or 2 inlets + 1 outlet) | Diverts or mixes the flow between circuits | HVAC temperature control, flow diversion |

Key Distinction:

Check valve types are automatic 2-way devices. When someone asks about 3-way check valve types, they typically mean systems using multiple check valves to control flow direction in complex piping arrangements, not a single valve with three ports.

How to Choose the Right Check Valve

Selecting the appropriate check valve types requires evaluating several system parameters and application requirements. Consider these factors for optimal check valve selection.

- Pipe Size

Small lines (25-50 mm) suit lift, wafer, or ball check valves. Medium lines (65-150 mm) work well with swing, dual plate, or wafer types. Large lines (200 mm+) typically require swing check valves for an acceptable pressure drop.

- Flow Velocity

High-velocity applications need fast-closing valves like dual-plate or spring-assisted types to prevent water hammer. Low-velocity systems can use standard swing check valve types. Calculate actual velocity to determine closing speed requirements.

- Pressure Rating

Match the valve pressure rating to the system design pressure with an appropriate safety margin.

Lift check valve types handle the highest pressures, while wafer types suit lower-pressure applications. Verify specifications include an adequate margin above the maximum operating pressure.

- Installation Space

Confined spaces benefit from wafer or dual-plate check valve types with compact face-to-face dimensions. Open installations can accommodate swing check valves. Measure available space before specifying valve type.

- Fluid Characteristics

Clean water suits any type. Fluids with suspended solids require ball check valves or swing types with fully supported discs.

Corrosive fluids need appropriate check valve materials. Consider temperature, viscosity, and chemical compatibility.

- System Type

Fire protection systems often use dual plate check valve types for reliability and water hammer prevention.

HVAC systems typically use wafer or swing types. Industrial processes may require lift check valves for tight shut-off and high-pressure handling.

- Check Valve Specifications Review:

Always review complete check valve specifications, including pressure rating, temperature limits, materials, and installation requirements, before final selection.

Consult manufacturer data sheets and verify compliance with applicable standards.

Habikon’s tips: Our engineering team helps you select compliant check valves that meet NFPA and Egyptian Fire Code requirements. We provide hydraulic calculations, valve specifications, and complete fire protection system design.

Get technical consultation today.

Check Valve Types Used in Fire Protection Systems

Fire protection systems in Egypt’s commercial and industrial projects require specific check valve types to ensure system reliability and code compliance.

| Application | Recommended Type | Key Requirements | Standards |

| Fire Pump Discharge | Dual plate or swing | UL/FM approved, prevents backflow | NFPA 20 |

| Sprinkler Risers | Wafer or dual plate | Maintain pressure, compact size | NFPA 13 |

| Backflow Prevention | Double-check assembly | Test ports, spring-loaded | Egyptian water code |

| Deluge Systems | Large swing | High flow capacity | NFPA 15 |

| Standpipes | Dual plate | Vertical installation, fast closing | NFPA 14 |

- Fire Pump Discharge Check Valves:

Dual plate or swing check valves prevent backflow that could damage pumps during shutdown. These must meet NFPA requirements and maintain a positive seal under all conditions.

- Riser Check Valves:

Installed at the base of sprinkler risers to maintain system pressure and prevent drainage. These check valve applications ensure immediate water availability during fire events.

- Backflow Preventers:

Double check valve assemblies prevent contamination of the water supply from fire protection systems. These use spring-loaded check valves with specific spacing and test ports per Egyptian water authority requirements.

- Egyptian Fire Code Compliance:

Check valve types in fire protection systems must be UL-listed or FM-approved and installed according to NFPA 13, NFPA 14, and Egyptian Fire Code requirements. Installation must allow for inspection, testing, and maintenance access.

Common Check Valve Problems and How to Prevent Them

Understanding typical check valve failures helps specify, install, and maintain systems properly.

- Water Hammer

Caused by fast-closing check valves or improperly sized valves in high-velocity systems.

Prevent by using dual plate check valves, installing water hammer arrestors, or selecting slow-closing designs for appropriate applications. Consider system velocity and valve closing speed during design.

- Chattering

Occurs when the disc repeatedly opens and closes due to turbulent flow or an undersized valve.

Resolve by proper sizing, installing in straight pipe sections away from elbows, or using spring-assisted types. Chattering indicates check valve performance issues requiring correction.

- Leaking

Results from worn sealing surfaces, debris on the valve seat, or incorrect installation. Prevent through proper filtration, regular maintenance, and correct orientation during installation. Inspect sealing surfaces during maintenance intervals.

- Disc Failure

Caused by water hammer impact, corrosion, or fatigue. Prevention can be achieved by selecting appropriate check valve materials, proper system design, and regular inspection. Replace worn components before complete failure occurs.

- Stuck Open

Debris, corrosion, or mechanical failure prevent disc closure. Prevent through filtration, proper material selection for the fluid, and periodic operation testing in critical systems.

Stuck valves compromise backflow prevention and system safety.

Additional Prevention Strategies:

- Inspect sealing surfaces during maintenance intervals

- Replace worn components before complete failure

- Test critical systems quarterly

- Document all maintenance activities

Check Valve Installation with Habikon

Habikon supplies and installs check valves as part of comprehensive fire protection and electromechanical systems across Egypt’s commercial and industrial projects.

Engineering Design Process

Our engineering team evaluates system requirements, flow conditions, and pressure parameters to specify the correct check valve type for each application. We consider Egyptian Code compliance, NFPA standards, and long-term check valve performance.

Check valve design includes pressure drop calculations, water hammer analysis, and material selection appropriate for operating conditions. We coordinate with fire alarm systems and other trades to ensure complete system integration.

System Integration

Check valves are coordinated with pumps, control valves, and other system components during design. We ensure proper placement for maintenance access and system testing. Integration with firefighting systems requires precise valve selection and positioning.

Professional Installation

Certified technicians install check valves according to manufacturer specifications and code requirements. Installation includes proper orientation, support, and alignment to prevent premature failure.

Flow direction arrows must match the system design, and the valve body must be properly supported.

Testing and Commissioning

All check valve installations undergo functional testing to verify proper operation, sealing performance, and integration with overall system controls. Testing confirms the valve opens at the specified cracking pressure and closes without leakage.

Documentation

Complete installation documentation includes check valve specifications, test results, and maintenance requirements for facility management teams. Documentation supports ongoing project management and maintenance planning.

Project Experience

Habikon has installed check valves in fire protection systems for hospitals, manufacturing facilities, commercial towers, and industrial complexes throughout Egypt. Our experience spans swing check valves in large fire pump installations to dual plate valves in high-rise sprinkler systems.

Planning a commercial or industrial project?

Habikon provides complete engineering and design services for fire protection and MEP systems. Our team handles valve selection, system integration, installation, and commissioning.

Contact us for professional consultation

Maintenance Requirements for Different Check Valve Types

| Valve Type | Inspection Items | Service Interval | Common Issues | Maintenance Actions |

| Swing Check | Hinge pin, disc, seating surfaces | 2-3 years | Worn hinge, binding | Replace the pin and verify free movement |

| Dual Plate | Springs, plates, and hinge mechanisms | 1-2 years | Spring corrosion | Inspect tension, clean debris |

| Wafer Check | Spring assembly, disc, seat | 2 years | Spring fatigue | Replace spring, verify closing speed |

| Lift Check | Guide surfaces, disc, seat, spring | 2-3 years | Debris buildup | Clean guides, inspect wear |

| Ball Check | Ball, seat, body | 3-4 years | Seal wear | Replace entire valve |

| Foot Valve | Strainer, ball/disc, seat | 1-2 years | Strainer clogging | Clean strainer, inspect seal |

All check valves in fire protection systems require annual testing per NFPA 25. Industrial and commercial applications should establish maintenance schedules based on system criticality and operating conditions. Document all maintenance activities and component replacements.

FAQs

How to size a check valve?

Match valve size to pipe size, then verify flow velocity and pressure drop using manufacturer curves. Valves should operate at 50-75% of maximum rated flow. For fire protection systems, follow hydraulic calculations and NFPA requirements. Undersized valves cause chattering; oversized valves may not seal properly at low flow.

What are the main types of check valves used in piping systems?

The six main types are swing, lift, wafer, dual plate, ball, and foot valves. Swing suits large pipes with low velocity. Lift handles high pressure. Wafer provides a compact design. A dual plate prevents water hammer. Ball handles solids. The foot maintains pump prime. Selection depends on pipe size, pressure, and flow conditions.

What is a swing check valve, and when should it be used?

A swing check valve uses a hinged disc for one-way flow control. Best for large diameter piping (100 mm+) in horizontal installations where low pressure drop matters. Ideal for water treatment, industrial processes, and large fire systems. Requires horizontal installation and may cause water hammer in high-velocity applications.

How do I read check valve symbols on engineering drawings?

Check valve symbols show an arrow indicating permitted flow direction with a barrier representing the closing element. Swing types show hinged discs.

- Lift types display vertical movement.

- The dual plate shows two plates from the center.

- Follow ISO 1219 and ISO 4126 standards.

- Egyptian drawings typically use ISO or BS standards.

What materials are check valves made from?

Common materials include brass (water, up to 120°C), stainless steel (harsh environments, up to 250°C), cast iron (large water systems), bronze (marine applications), and PVC (corrosive chemicals).

Material selection depends on fluid type, temperature, pressure, and corrosion potential. Fire systems typically use ductile iron or stainless steel.

What is the difference between a swing check valve and a lift check valve?

Swing valves use hinged discs for horizontal installation with low pressure drop. Lift valves use vertical disc movement for high-pressure applications with tighter shut-off. Swing suits, large pipes, and low velocity.

Lift excels in high-pressure systems and vertical piping. Both serve different applications based on system requirements.